Bermuda Triangle

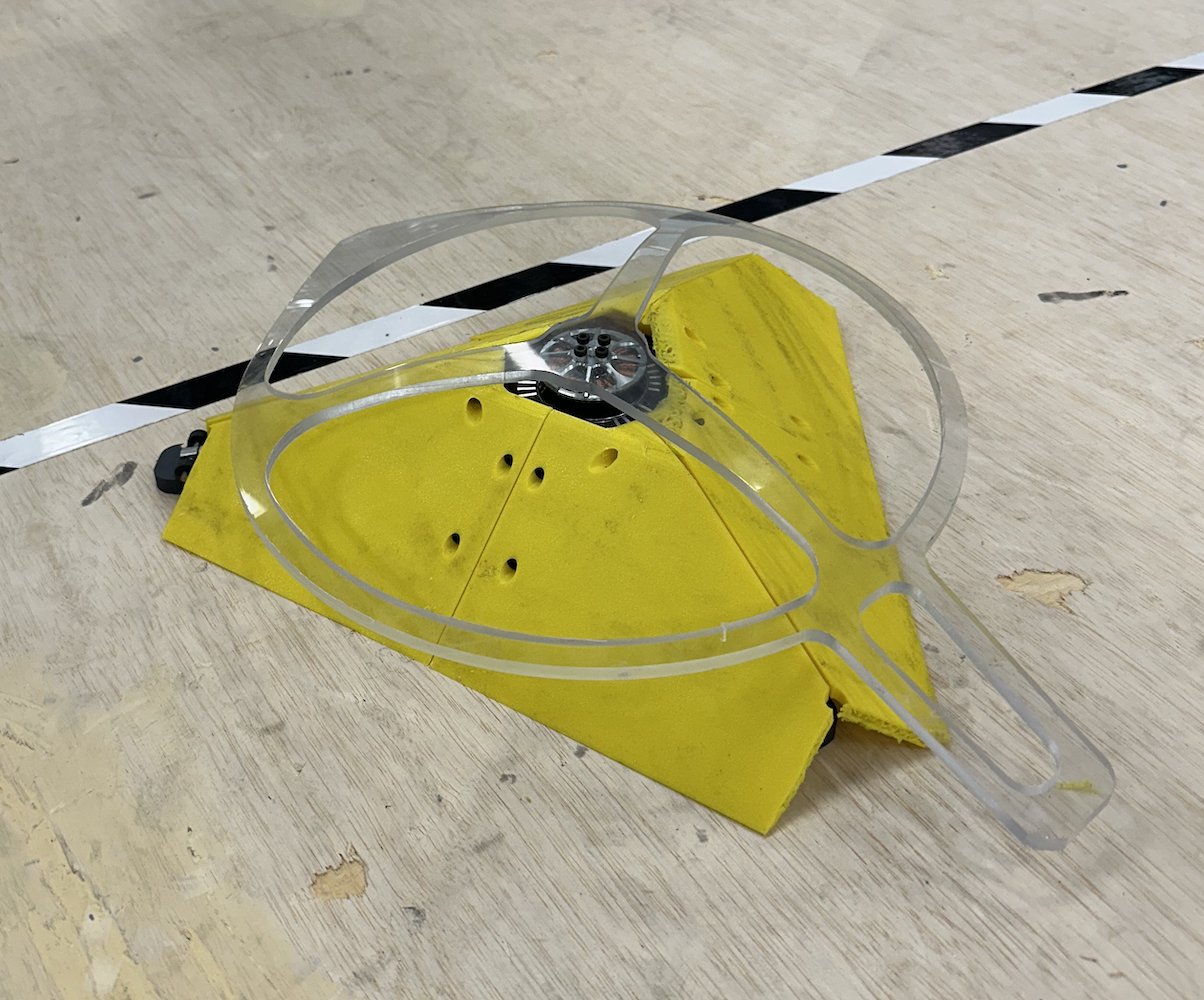

This was an Antweight Battlebot designed to compete in the Siemens Energy OIC Showcase. Competition rules required that nearly all components be made from plastic, with the structure and armor 3D printed from an approved materials list.

Overview

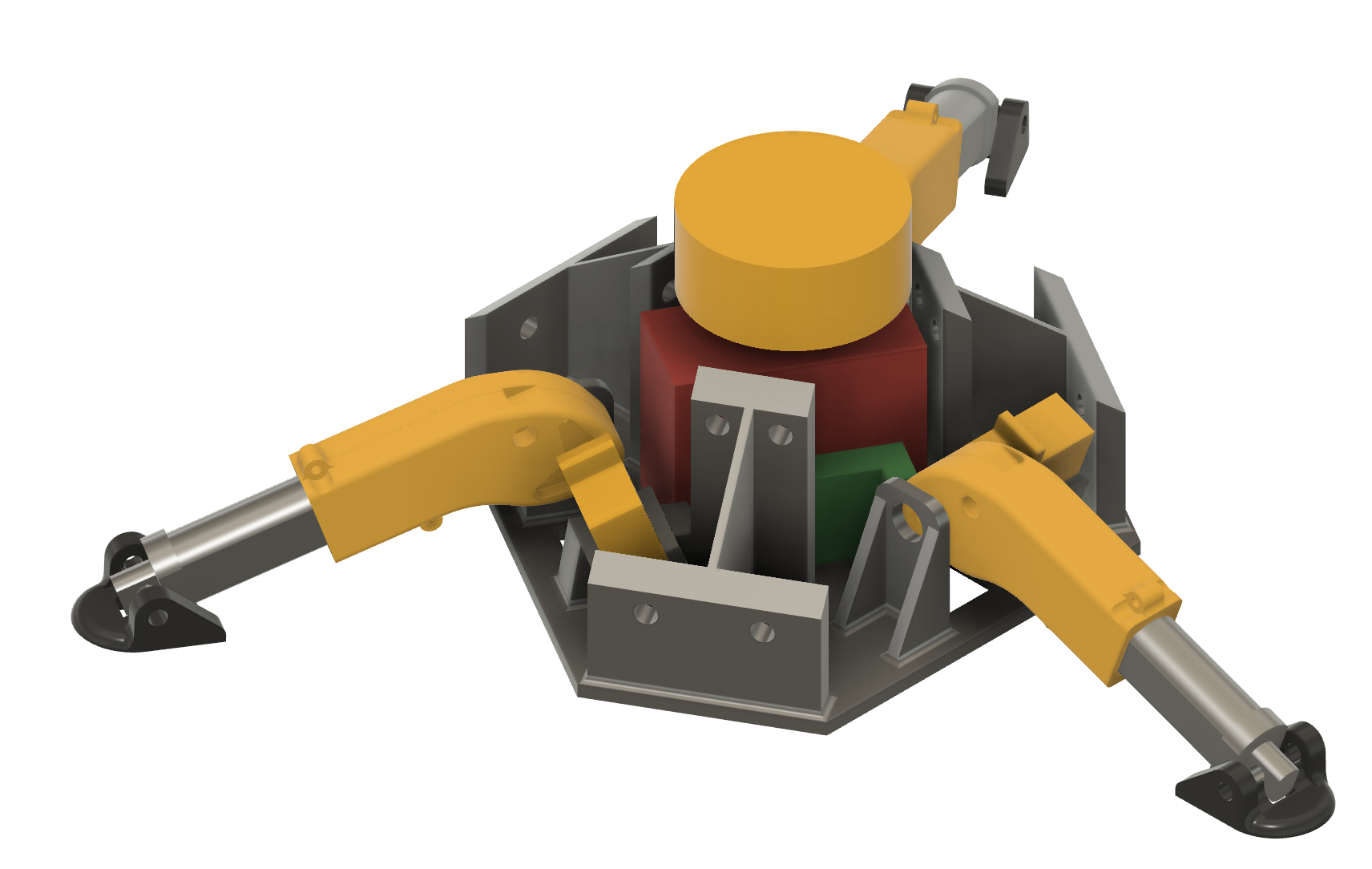

This robot qualifies as a walker, granting it an increased weight allowance. A heavy polycarbonate weapon stores significant kinetic energy, while an ELEGOO Nano controls three legs made of micro servos and custom-designed linear actuators. These components work together to keep the robot’s center of mass low and its profile close to the ground while delivering powerful blows.

Design Philosophy

I explored several solutions, but there were several reasons that I settled on this design:

Walking classification provides a 2x weight bonus, enabling heavier armor and weaponry

Near-parallel linear actuators keep the center of mass low while walking; micro servos lift the legs off the ground while remaining enclosed in a rigid armor shell

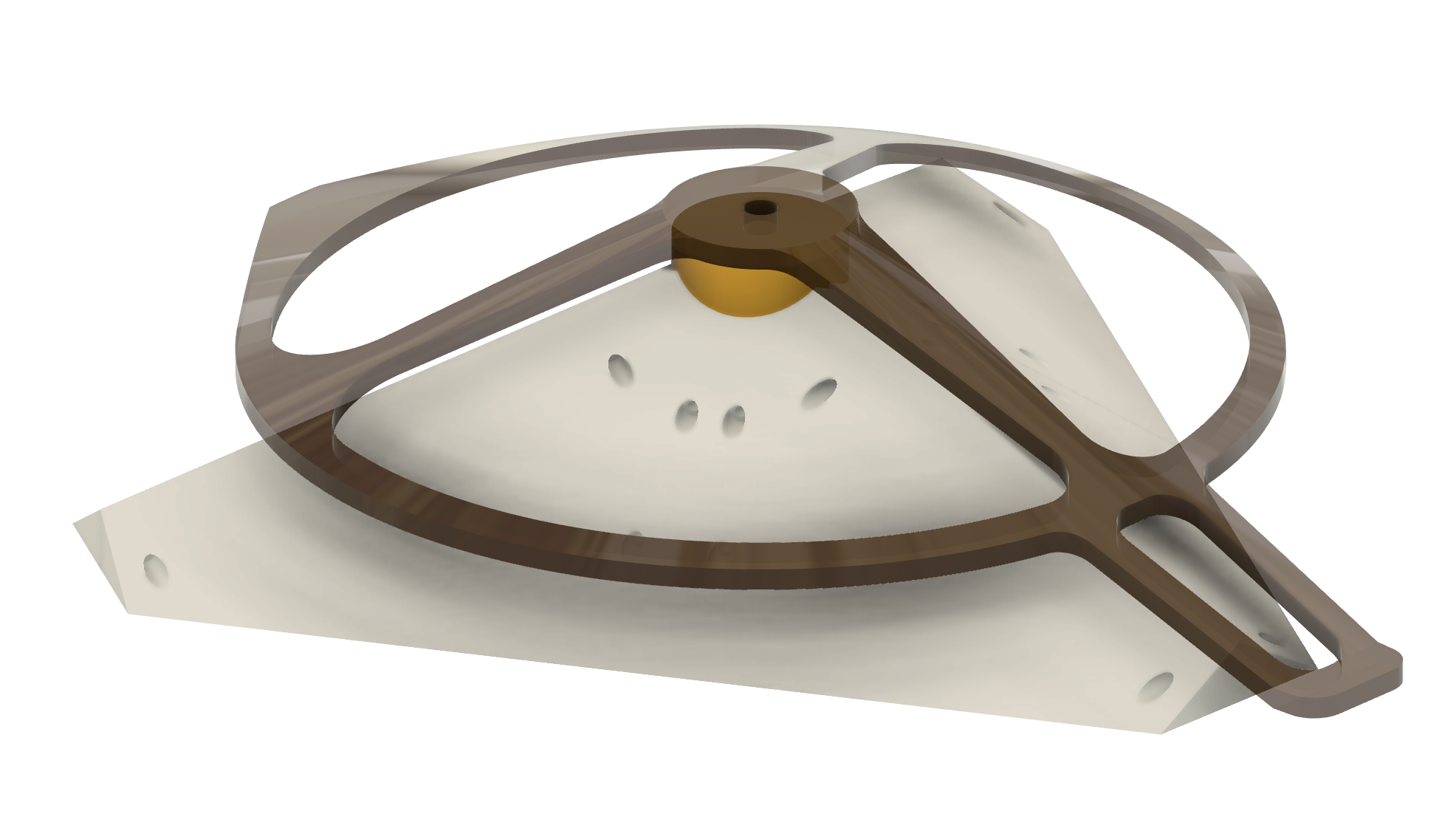

A large, asymmetric weapon increases the likelihood of landing a direct hit

Ring-shaped weapon maximizes moment of inertia while keeping mass centered on the motor shaft, improving stability and efficiency

Conical shape deflects low hitting bots and flippers from all directions

Truss-shaped chassis and armor improve strength without excessive material use

Sloped side plates help resist flipping and distribute impact forces to the ground

Design Features

~180g conical spinner

Verified strength in FEA using static and impact* simulations

~740 kV brushless motor for weapon

Linear actuators are customized to reduce weight and rigidly attach to servo motors

3D printed ABS casing replaces aluminum design, cutting ~120g of weight

Attaches to nylon servo horn to minimize moving parts

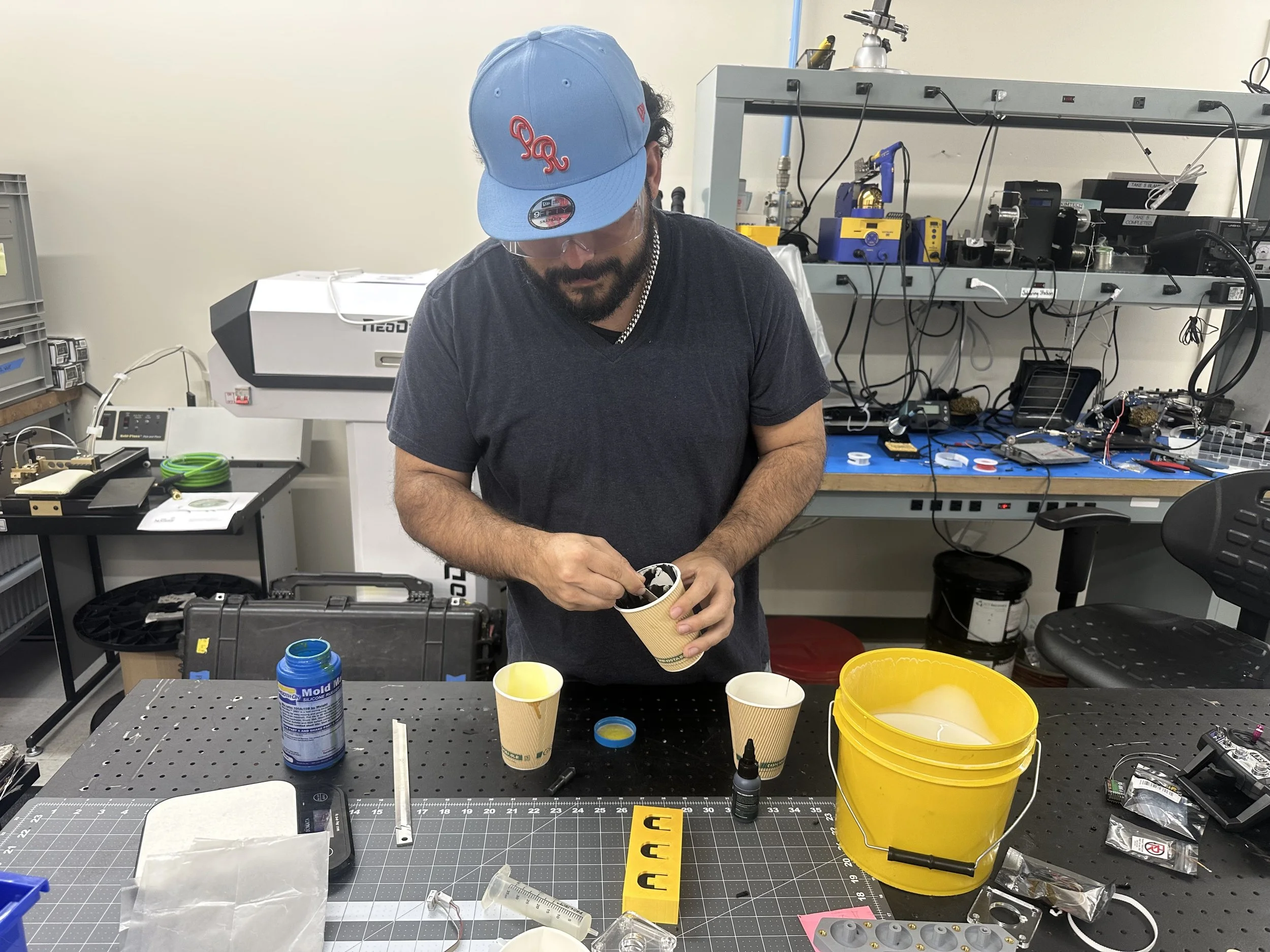

Silicone molded feet provide traction with the floor

Materials and Manufacturing Process

3D printed ABS for chassis and armor

Utilized block modifiers in Bambu Studio while slicing to intentionally increase material where it’s needed and reduce material where it’s not

Weapon cut from ¼” polycarbonate sheet via CNC router and thermoformed in a conical mold using a controlled oven ramp

* Since the non-linear properties of polycarbonate was not in Fusion 360’s library, impact results were mostly used to qualitative inform design